Steel with a hollow section whose length is much greater than the diameter or circumference. According to the cross-sectional shape, it is divided into circular, square, rectangular and special-shaped steel pipes; according to the material, it is divided into carbon structural steel pipes, low-alloy structural steel pipes, alloy steel pipes and composite steel pipes; Steel pipes for thermal equipment, petrochemical industry, machinery manufacturing, geological drilling, high-pressure equipment, etc.; according to the production process, they are divided into seamless steel pipes and welded steel pipes, of which seamless steel pipes are divided into hot-rolled and cold-rolled (drawn) Two types, welded steel pipes are divided into straight seam welded steel pipes and spiral seam welded steel pipes.

Steel pipes are not only used for conveying fluids and powdered solids, exchanging thermal energy, making machine parts and containers, but also an economical steel. Using steel pipes to make building structure grids, pillars and mechanical supports can reduce weight, save 20-40% of metal, and realize factory-based mechanized construction. Using steel pipes to manufacture highway bridges can not only save steel and simplify construction, but also greatly reduce the area of protective coating, saving investment and maintenance costs.

By production method

Steel pipes can be divided into two categories according to the production method: seamless steel pipes and welded steel pipes. Welded steel pipes are referred to as welded pipes for short.

1. According to the production method, seamless steel pipes can be divided into: hot rolled seamless pipes, cold drawn pipes, precision steel pipes, hot expanded pipes, cold spinning pipes and extruded pipes, etc.

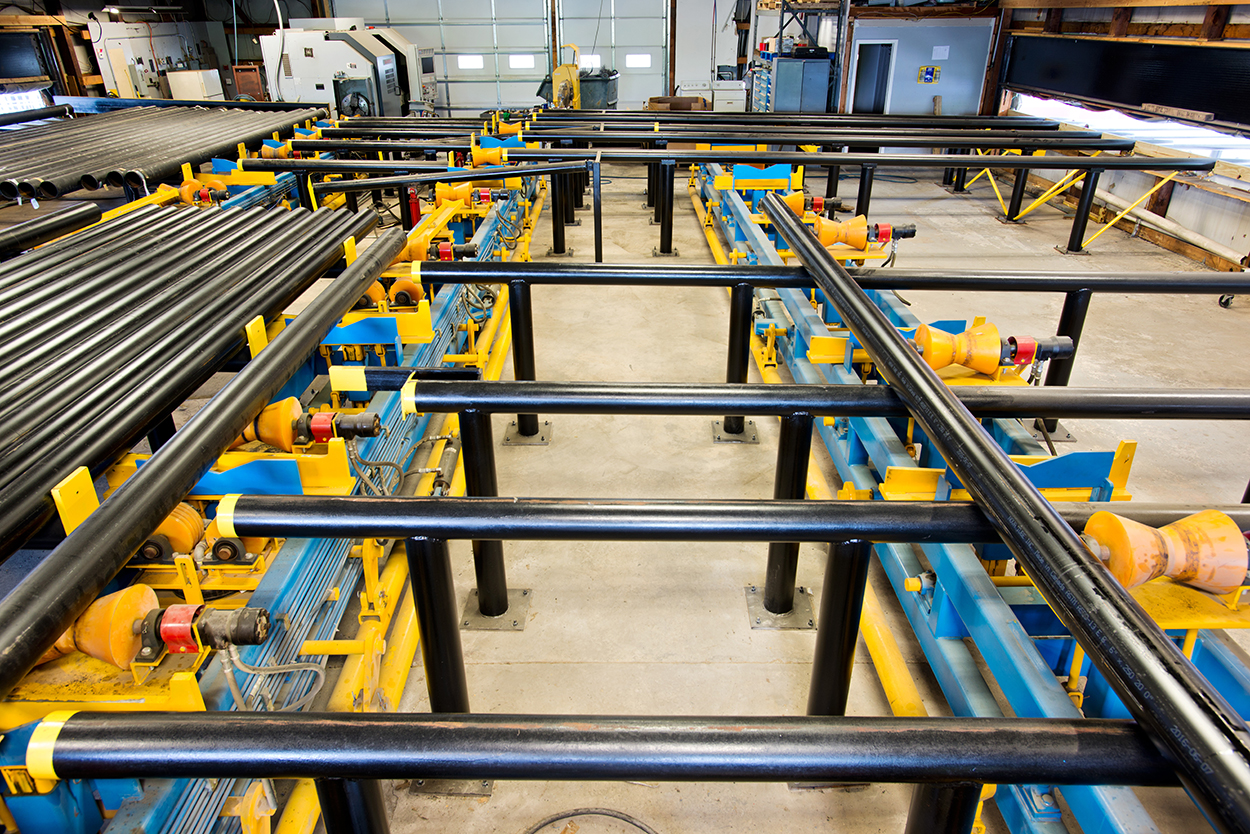

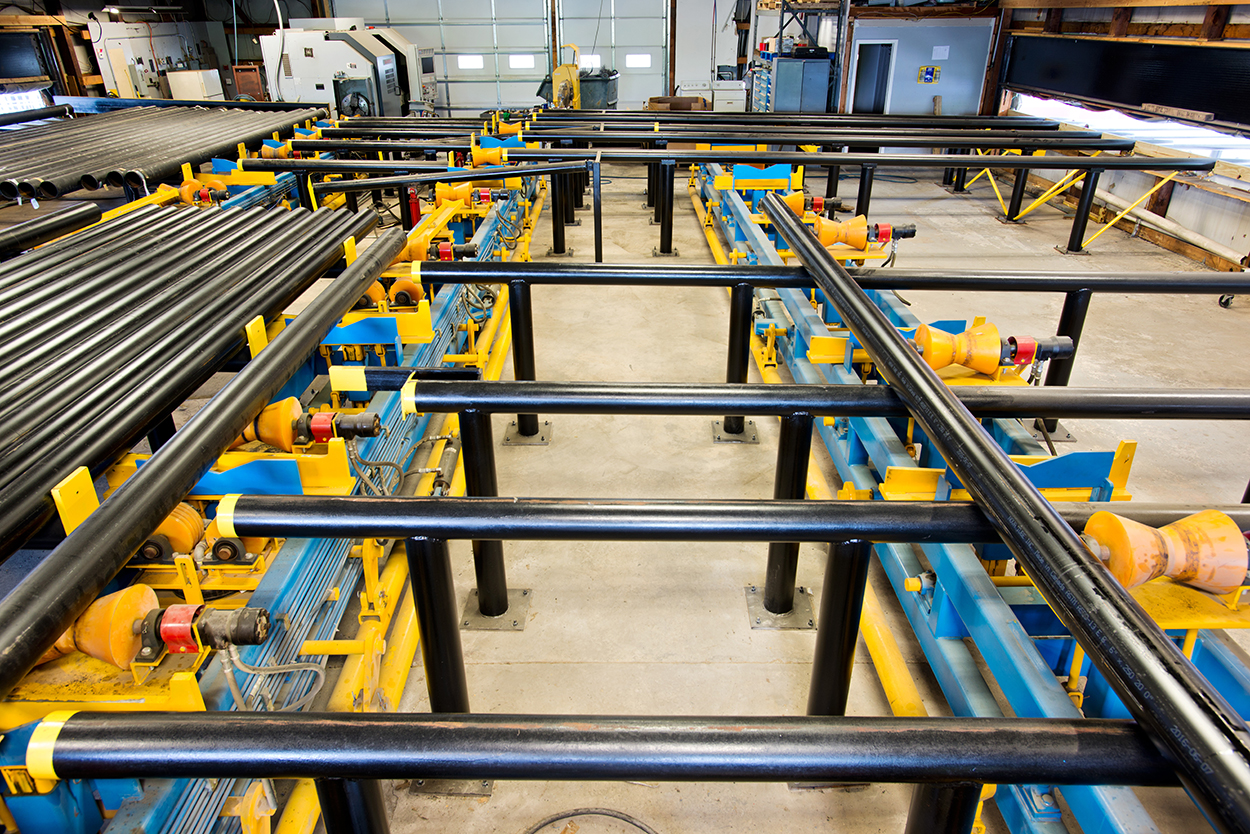

bundles of steel pipes

Seamless steel pipes are made of high-quality carbon steel or alloy steel, and are divided into hot-rolled and cold-rolled (drawn).

2. Welded steel pipes are divided into furnace welded pipes, electric welding (resistance welding) pipes and automatic arc welded pipes because of their different welding processes. They are divided into straight seam welded pipes and spiral welded pipes because of their different welding forms. For round welded pipes and special-shaped (square, flat, etc.) welded pipes.

Welded steel pipes are made of rolled steel plates with butt or spiral seams. In terms of manufacturing methods, they are further divided into welded steel pipes for low-pressure fluid transportation, spiral seam electric welded steel pipes, direct coiled welded steel pipes, and electric welded pipes. Seamless steel pipes can be used for liquid pneumatic pipelines and gas pipelines in various industries. Welded pipes can be used for water pipes, gas pipes, heating pipes, electrical pipes, etc.

Material classification

Steel pipes can be divided into carbon pipes, alloy pipes, stainless steel pipes, etc. according to the pipe material (ie steel type).

Carbon pipes can be further divided into ordinary carbon steel pipes and high-quality carbon structural pipes.

Alloy tubes can be further divided into: low alloy tubes, alloy structural tubes, high alloy tubes, and high strength tubes. Bearing tubes, heat- and acid-resistant stainless tubes, precision alloy (such as Kovar) tubes, and superalloy tubes, etc.

Connection method classification

According to the connection method of the pipe end, the steel pipe can be divided into: bare pipe (the pipe end is not threaded) and wire pipe (the pipe end is threaded).

The wire tube is further divided into: ordinary wire tube and tube end thickened wire tube.

Thickened wire tube can also be divided into: external thickening (with external thread), internal thickening (with internal thread) and internal and external thickening (with internal and external thread) and other threading tubes.

According to the thread type, the threading pipe can also be divided into: ordinary cylindrical or conical thread and special threading and other threading pipes.

In addition, according to the needs of users, the wire tube is generally equipped with pipe joints for delivery.

Classification of coating characteristics

According to the characteristics of surface coating, the steel pipe can be divided into: black pipe (uncoated) and coated pipe.

Coated pipes include galvanized pipes, aluminized pipes, chrome-plated pipes, aluminized pipes and other alloy-layered steel pipes.

Coated tubes include outer coating tubes, inner coating tubes, and inner and outer coating tubes. The commonly used coatings include plastics, epoxy resins, coal tar epoxy resins and various glass-type anti-corrosion coatings.

Galvanized pipe is further divided into: KBG pipe, JDG pipe, threaded pipe, etc.

Classification use classification

1. Pipes for pipes. Such as: seamless pipes for water, gas pipes, steam pipes, oil pipelines, and pipes for oil and natural gas trunk lines. Agricultural irrigation faucets with pipes and sprinkler irrigation pipes, etc.

2. Tubes for thermal equipment. Such as boiling water pipes, superheated steam pipes for general boilers, superheating pipes, large smoke pipes, small smoke pipes, arch brick pipes and high temperature and high pressure boiler pipes for locomotive boilers.

3. Pipes for machinery industry. Such as aviation structural pipes (round pipes, elliptical pipes, flat elliptical pipes), automobile semi-axle pipes, axle pipes, automobile tractor structural pipes, tractor oil cooler pipes, agricultural machinery square pipes and rectangular pipes, transformer pipes and bearings. tube etc.

4. Pipes for petroleum geological drilling. Such as: oil drill pipe, oil drill pipe (kelly and hexagonal drill pipe), drill pipe, oil tubing, oil casing and various pipe joints, geological drilling pipe (core pipe, casing, active drill pipe, drill pipe) , press hoop and pin joints, etc.).

5. Chemical industry pipes. Such as: oil cracking pipes, chemical equipment heat exchangers and pipes, stainless acid-resistant pipes, high-pressure pipes for fertilizers, and pipes for transporting chemical media, etc.

6. Other departments use pipes. Such as: tubes for containers (tubes for high-pressure gas cylinders and tubes for general containers), tubes for instrumentation, tubes for watch cases, injection needles and tubes for medical devices, etc.

Section shape classification

The steel grades and varieties of steel pipe products are extremely diverse, and their performance requirements are also various. All of these should be differentiated as user requirements or working conditions change. Generally, steel pipe products are classified according to cross-sectional shape, production method, pipe material, connection method, coating characteristics and application, etc.

Steel pipes can be divided into round steel pipes and special-shaped steel pipes according to the cross-sectional shape.

Special-shaped steel pipes refer to steel pipes with various non-circular cross-sections.

English

English Español

Español