Copper Pipe & Tubes Size:1/4 NB TO 12" NB 3 MM OD TO 114.3 MM OD

Copper Pipe & Tubes Wall Thickness:Schedule 10 to Schedule 160

Copper Pipe & Tubes Length:5 to 7 Meters, 09 to 13 Meters, Single Random Length, Double Random Length And Customize Size.

Form:Round, Square, Rectangular, Coil, U Tube,

Type:Seamless / ERW / Welded / Fabricated

Type L and Type M copper pipe

Type K pipe", "Type L pipe", "Type M pipe", and "Type DWV pipe"-U.S. and Canada

"Type A", "Type B", "Type C", and "Type D" -Australia standard

EN 1057 "Type X", "Type Y" and "Type Z" -Europe standard

Surface:Black painting, varnish paint, anti rust oil, hot galvanized, cold galvanized, 3PE

Copper Pipe & Tubes Pipe Ends:Plain Ends / Beveled Ends

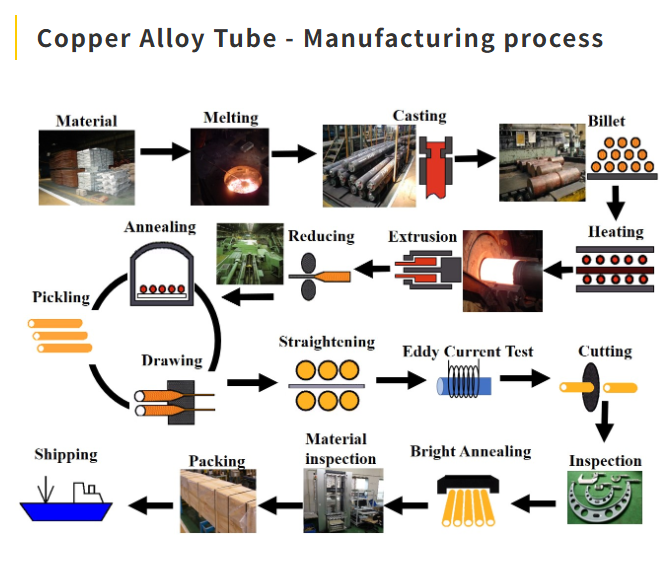

Copper Pipe & Tubes Delivery Conditions:As Rolled, Cold Drawn, Hot Finish, Stress Relieved, Annealed, Hardened, Tempered

Copper Pipe & Tubes Coating Electro:polish, Mechanical Polish, Satin Finish, Passivated

Copper Pipe & Tubes Other Testing:NACE MRO175, Hardness Test, Flare, Hydrostatic Test, Eddy Current test, Grain Size Test, Eddy Current, Annealed, Tempered, Stress Relieved etc.

Copper Pipe & Tubes Dimension:All Pipes Is Manufactured and Inspected / Tested to the Relevant standards including ASTM And ASME

Copper Pipe & Tubes Value Added Services:Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment

Copper Pipe & Tubes Packaging:Loose / Bundle / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector

Features:

- High strength

- High resistance to pitting, crevice corrosion resistance

- High resistance to stress corrosion cracking, corrosion fatigue and erosion

- Good sulfide stress corrosion resistance

- Low thermal expansion and higher heat conductivity than austenitic steels

- Good workability and weldability.

- High energy absorption.

- Dimensional accuracy

- Excellent finish

- Durable

- Leak proof

- Thermal resistance

- Chemical resistance

Applications :

- use in Instrumentation

- use in Hydraulic & Pneumatic system

- use in Automotive industries

- use in Structural Purposes

- use in Medical

- use in Pharmaceutical

- use in Economizers

- Use in Condenser

- Use in Furniture industries

- Use in domestic applications

- Use in bus body

- Use in fencing

- Use in Pulp and paper

- Use in Offshore construction

- Use in Food and pharmaceutical processing

- Use in Desalination and wastewater projects

- Use in Electrical Submersible Pump

English

English Español

Español