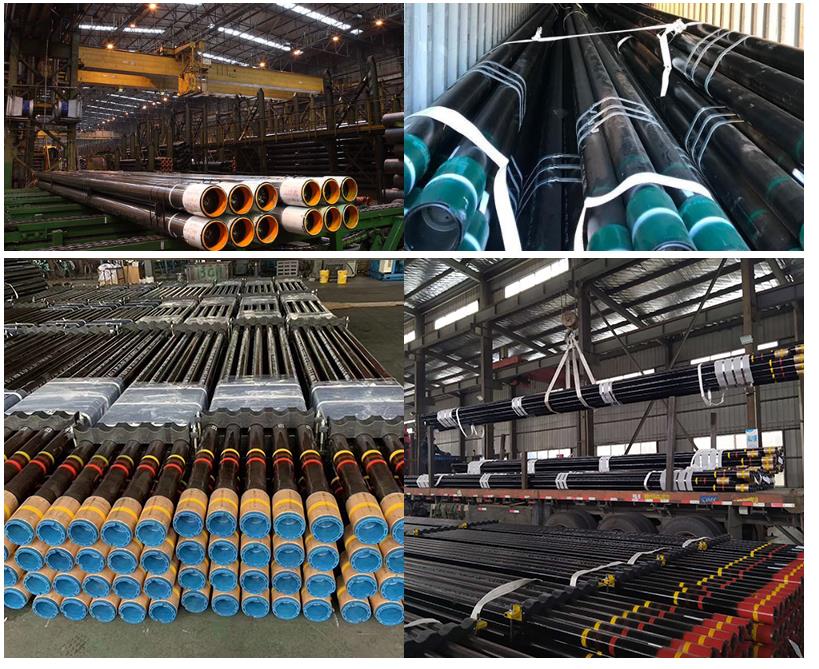

Pipe Type:Oil casing, API 5CT casing,API Spec 5CT J55 K55 N80 L80 Casing Pipe;Seamless Steel Oil Well Casing Pipe

Outer diamater(OD):114.30mm-508mm

Wall thickness(WT):5.21mm-16.13mm

Length:R1; R2; R3

Gread:J55;K55;N80-Q;L80-1;L80-9Cr;L80-13Cr,C95,P10

Standard: API 5CT PSL1/PSL2 J55,K55,N80-1,N80-Q,

API 5CT PSL1/PSL2 L80-1, L80-9Cr,L80-13Cr,C90, C95, P110, Q125

Thread types: STC;LTC;BTC;VAM TOP equivalent;New VAM equivalent;CS equivalent;HSC equivalent;NUE;EUE;LTC;XC

Thread: NUE, EUE, VAM, STC, LTC, BTC, XC, VAM TOP, NEW VAM,HYDRILL CS

Application: Casing Pipe is widely used for fastening oil and gas well wall or borehold, with bigger diameter than tubing, including surface casings, technical casings and oil layer casings.

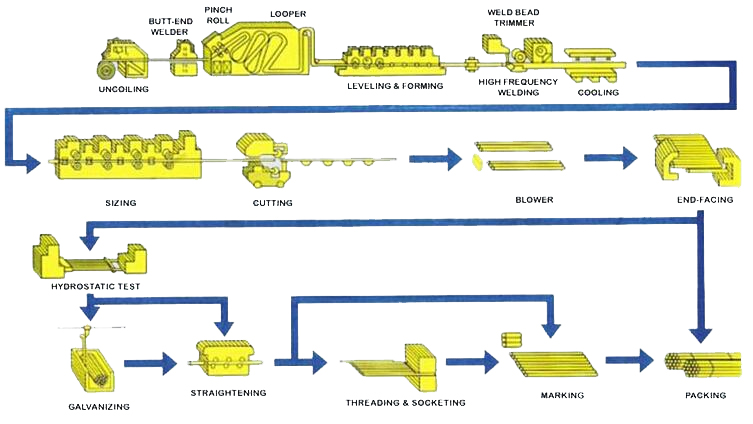

Production technology: Plain pipe-end upsetting- Austenite treatment-Quenching-Tempering-straightening-(Non-Destructive Testing)- Threading-Thread inspection-coupling MPI-phosphating-Coupling make up-Drifting-Hydrostatic testing-Measuring&Weight-Marking&Stenciling-Coating-Packing Casing and tubing-Transportation

vailable Sizes

Category: ERW, HFW or SMLS

Standards:H-40, J-55, K-55, C-75, L-80, N-80, C-95, AS-95, P-110, L80-13CR

Steel Grade: H40, J55, K55, N80

Connections

API 5CT is applicable to following connections which complied with API SPEC 5B:

• SC: Short round thread casing

• LC: Long ound thread casing

• BC: Buttress thread casing

• NU: Non-upset tubing

• EU: External upset tubing

English

English Español

Español