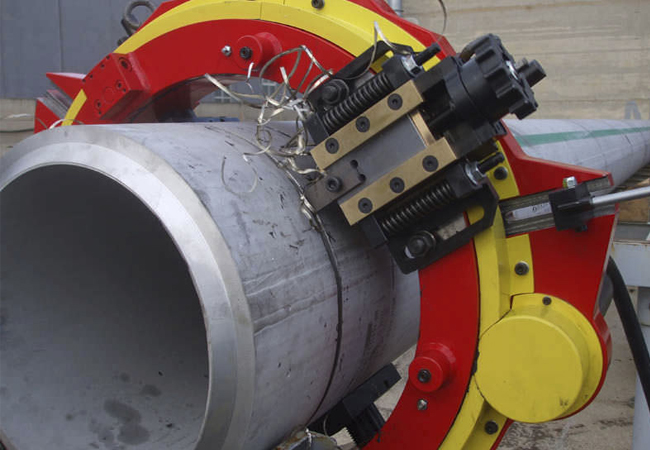

Pipe welding or pipe connection is a method where two pipes are joined together. This process can be achieved by various welding methods, such as arc welding, MIG welding, TIG welding and several other welding techniques. We weld all kinds of piping constructions of different sizes and shapes.

1:SMAW: SHIELDED METAL ARC WELDING

Shielded metal arc welding, frequently referred to as stick welding, is a very common and popular method of welding. It is typically used in construction, steel fabrication, pipeline work and for repairing heavy equipment.

2:GMAW: GAS METAL ARC WELDING

This type of welding—also called MIG (Metal Inert Gas) Welding—also uses a consumable electrode. However, in MIG welding, the electrode is a solid wire that is constantly fed through the welding gun. MIG welding machines are designed to accommodate varying sizes and gauges of these welding wires.

3:GTAW: GAS TUNGSTEN ARC WELDING

This type of welding is known by several common names—TIG Welding, Heliarc Welding and Gas Tungsten Arc Welding. Unlike the other types of welding mentioned so far, this type does not use a consumable electrode. Instead, the welder uses an external rod to create the molten metal needed to forge the weld.

English

English Español

Español