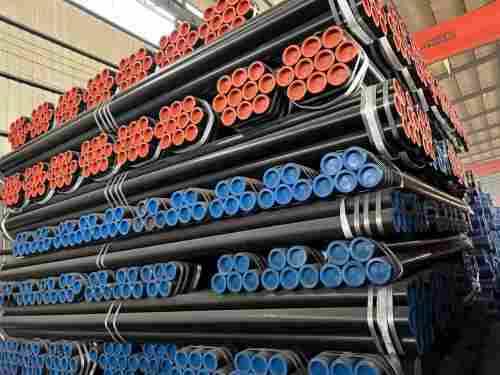

Pickling treatment of carbon steel tubes

In modern industrial applications, carbon steel tubes are extensively used across various fields such as petroleum, chemicals, and power generation due to their excellent mechanical properties and cost-effectiveness. However, during the manufacturing, transportation, and installation processes, carbon steel tubes often accumulate scale, rust, and other impurities on their surface. These deposits not only affect the aesthetic appearance of the pipes but can also reduce their durability and compromise safety. As a result, pickling treatment has become an essential step in the surface treatment of carbon steel tubes.

Feb 19, 2025

read more

English

English Español

Español